“smart” carton identification and labeling system

Package Trak

Our automated system utilizes current connectivity to provide real time communication to immediately identify and determine the business requirements for each carton, including the label format and data specifications. Labels are printed, applied and validated to ensure accuracy and communicated downstream to additional applications. Smart solutions – more accuracy – improved efficiency.

How Package Trak Works

Interface

- Maintains communication between your Warehouse Management System (WMS) server, Oracle, etc., and Package Trak’s controlling PC.

- Interfaces with a variety of host systems such as SAP

- Retrieves and stores data in real time during the manufacturing process.

Control/Identification

- Precisely tracks movement of cartons being transported down one or multiple conveyor lines.

- Enable or disable the printer/applicator(s) based upon the package criteria

- Starts or stops the induct conveyor to ensure carton spacing

- Determine which cartons should only receive shipping labels and/or detailed packing list labels when controlling multiple carton orders

- Divert mislabeled, or unlabeled, cartons down a reject spur for subsequent manual processing

Weigh Scale

- Incorporate data from a weigh scale into a label format, transmitting to your shipping/host system to calculate correct freight charges.

Labeling

- Format, prints and applies the label with the data specified for each carton.

- Production speeds of up to 60 cartons per minute

- Labels can be generated by using pre-formatted versions directly from the server or by retrieving the required data fields and formatting the label accordingly

- Control automatic printer/applicators as well as stand-alone printers

Validation

- Verification that the applied shipping or packing list label is correct for that specific carton and update the server.

Security

- Prevent unauthorized use of the system by establishing authorized log-on names and passwords, as well as event logs to track activity.

Turn-Key Solution

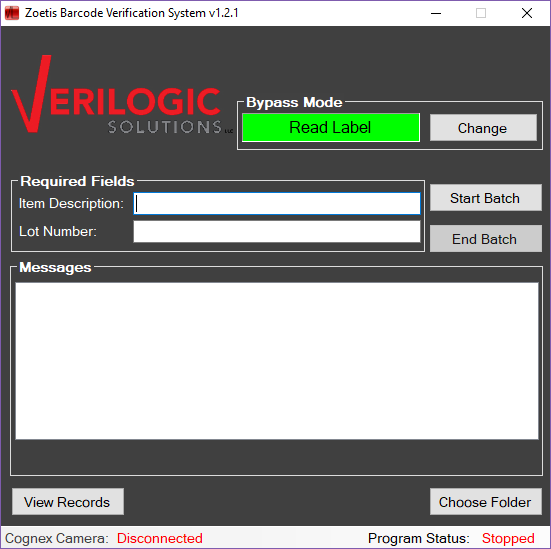

System Software – Verilogic system software brings it all together. From the WMS to the individual system components. Our software is custom tailored to meet your business needs.

System Software – Verilogic system software brings it all together. From the WMS to the individual system components. Our software is custom tailored to meet your business needs.

Control PC – Verilogic can provide Industrial PC’s running Windows Embedded operating System with our systems. These industrial hardened systems have no moving parts and include a 5 year warranty.

Case or Item Labels – The Verilogic system software automatically generates the package, case or item label required to Uniquely identifies each pallet in the supply chain.

Case Label Printer-Applicator – Various types of label printer applicators can be adapted to your product. The Blow On Printer applicator shown here is often a great match for case labeling. All applicators utilize off the shelf components and Zebra print engines.

Induct and Verification Scanners/Imagers- Used to identify products on induct to the labeling system as well as to verify products have been correctly labeled.

PLC Control Interface- Used to signal the conveyor controller and other devices on the line based on events occurring during the labeling process.